The QC System

Incoming Quality Control

We make sure that every product is up to our high-quality standards. Before packaging, we examine the accessories for any damage. Once our workers receive the accessories in our warehouse, each and every item is thoroughly checked by our workers. All the accessories go through a quality assurance process carried out by our inspectors. If any accessory does not meet the quality standard, it gets eliminated. Only the accessories that are up to the technical standard are used in the production process.

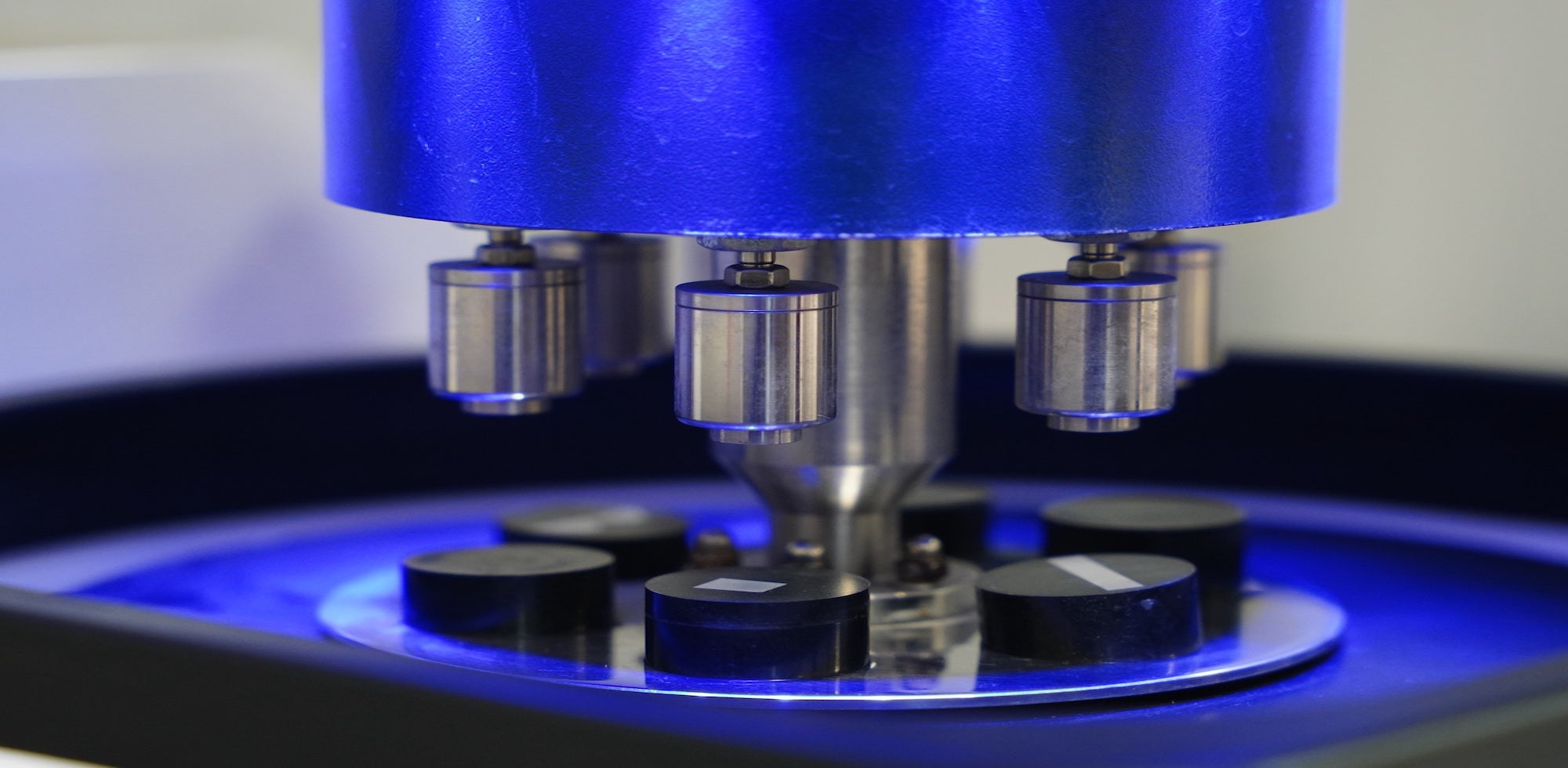

Process Quality Control

Our team of highly experienced individuals tests the E-bike frame for any fatigue. For example, the frame is checked to see whether it has any cracks or if there is any problem with the shock absorption function. If the frame passes the test, only then we proceed to paint the frames and spray brand logos.

If we have a sample E-bike in production, its design, build quality, functions, and performance will be tested, and an experimental report will be made. We will only proceed with the mass production of E-bikes once the sample bike passes the quality assurance test and becomes qualified. While assembling the bicycles, if any issues related to angle shifting or braking occur, all will be solved immediately on the spot.immediately, if there are any problems in braking, shifting, and driving angle.

Final Quality Control

After completing the assembly process, all the E-bikes will be tested again for final quality assurance. Generally, we test the bikes after assembly for three types of inspections:

Visual Inspection: Our team checks whether there are any scratches on the bike. We further analyze if all the parts of the E-bike, like the chain, tire, connector, and saddle, are properly assembled and aligned in accordance with each other.

Functional Inspection: After visual inspection, we test the bike for functionality. For example, we take a test ride to see if the bike is moving across all directions properly. We also check if the LCD display is working fine(displaying parameters correctly), the pedal shifting, the motor's sound, and the installation of tires and spokes.

Performance Inspection: At last, we check our bikes for performance which means that we do a variety of tests like climbing tests, braking tests, speed tests, shock absorption tests, and more to make sure the performance of the bike is optimal.

Outgoing Quality Control

Before shipping products, the XNT factory strictly adheres to its agreement with dealers and thoroughly inspects each item. This inspection includes verification of user manuals, accessories such as mudguards, power adapters(chargers), lighting devices, keys, item lists, and outer box labels are also checked for accuracy.